2024 Scrap Metal Recycling Plant Waste Scrap Car Aluminium Steel Recycling Line System

Applicable Materials:

Automobile shells, Scrap aluminum, Scrap steel, Scrap metal, Paint buckets, Color steel tiles, Iron briquettes, Motorcycle racks, Bicycle racks, Scrap home appliances, Carriage boards, Keel bars, Rolling shutters, Scrap angle iron, scrap iron. etc.

Power :15kw-160 KW Production :5-60 Tons/Hour

- Fitted Solution and Offer , 24 Hours Online.

- Oversea Installation , Training on Request .

- Continue provide Wearing Parts and Service !

Video

Description

2024 Scrap Metal Recycling Line Waste Scrap Car Auto Aluminium Steel Recycling Plant System

Scrap Metal Recycling Plant

Kowloon scrap metal recycling plant is designed to recycle ferrous and non-ferrous metal scrap, which is cost-effective, safe and durable.

Scrap metal recycling plant adopts a specially designed heavy duty Metal Shredder for the preliminary shredding, and a heavy-duty shredder or hammer mill for further processing. After that a Dust collection system for removing the dust, a powerful magnetic separator is used for separating the ferrous metal, and an effective eddy current separator to remove the non-ferrous steel.

METAL SHREDDER

Kowloon Metal Shredder is specially designed for shredding scrap metal into clean-cut primary scraps down to size. with the special design of low speed, high torgue operation, minimized noise and power consumption high production. The output will be pre-shreded metal strips.

Metal shredder features a patented knife system manufactured for extremely durable and easily-replacing knife which result in giving the input metal clean and fast cut. The unique structure of the knives in this machine can provide over hundreds of thousand tons working life. And the knives can be replaced partly to save maintenance time and cost for our customer. It is widely used scrap metal recycling plant.

New designed double shaft shredder is using the planetary driving method of the motor and reducer to tear the metals into smaller pieces of metals .

The shaft takes the spline type , which is much more powerful than the tradtional driving method of the V belt .

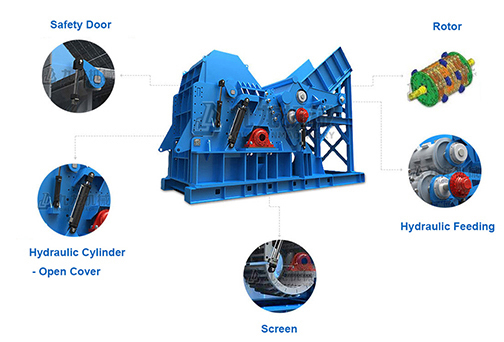

METAL CRUSHER

Kowloon metal crusher is a kind of mechanical equipment produced by our company, which is specialized in crushing and recycling scrap steel.

Application Materials :

Scrap steel, bicycles, motorcycles, car shells, cans, paint buckets, iron sheets, color steel tiles, waste light and thin metal materials, etc.

Working principle

The metal is fed into the forced feeding and crushing port of the equipment through the feeding conveying device, and the metal is primary crushed by the crushing process of the pressing roller and the primary crushing shaft. After the primary crushing, the metal enters the main cavity of the equipment.

Driven by the torque motor, the hammers on the rotor of the main machine take turns to hit the objects to be crushed that enter the cavity. The materials pass through the air cyclone sorting system to separate the paint, rust and waste plastics in the metal, and the materials discharged at the bottom of the equipment are transported to the collecting point through the conveying equipment.

VIBRATION FEEDER

Kowloon vibrating feeder uses the centrifugal force generated by the rotation of the eccentric block to make some movable parts, such as the frame and the screen bar, move continuously.

The vibrating exciter is the vibration source of the whole equipment. It is composed of two eccentric shafts and one gear. When the motor drives the driving shaft through a triangle belt, gears on the driving shaft will engage to rotate the passive shaft. Then the two shafts rotate in reverse at the same time, making the frame vibrates and the material flows continuously to achieve the purpose of material conveying.

Kowloon Vibratory feeders with a vibratory feeder unit, an electromagnetic drive system, and a tray or trough for moving bulk dry materials such as powders, from a storage vessel such as a hopper into other processes or conveying systems. The feeders are powered by electromagnetic drives, and they create vibration that conveys material in the trough at a consistent, controlled speed and volume.

MAGNETIC DRUM SEPARATOR

It consists of screen box, oscillating motor, eccentricity block, oscillation system and under frame.

The oscillation system is driven by two same type oscillating motors, which make the screen box supported on the vibrator to vibrate linearly. The scrap is transported from the feed side to the discharging gate along the screen box to loose and separate the waste at the same time.

Kowloon magnetic drum separators are used to separate tramp iron from bulk material of all kind. Bulk material is fed via a chute or vibrating feeder to the separator and is conveyed by the roatation of the drum casing. Magnetic particles are attracted by the internal permanent magnet, whereas nonmagnetic particles follow their flight path determined by interia and gravity. The attracted material is conveyed by the drum shell to the end of the magnetic field and dropped to the other side of an adjustable splitter.

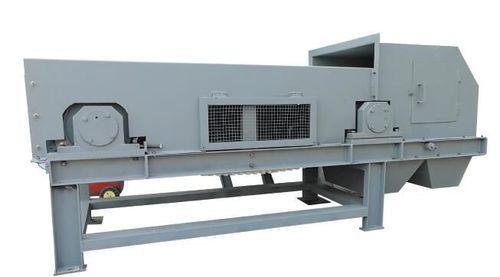

EDDY CURRENT SORTER

Eddy current sorting different size (10-30mm, 30-100mm)

Eddy current separator is an effective non-ferrous metal recycling method. It has the advantages of excellent sorting effect, strong adaptability, reliable mechanical structure, light structure, strong repulsion (adjustable), high sorting efficiency and large processing capacity, etc. It can separate some non-ferrous metals from electronic waste, The eddy current separator is mainly used in the electronic waste recycling production line to separate non-ferrous metals such as copper and aluminum from mixed materials, and can also be popularized and applied in the field of environmental protection, especially in the non-ferrous metal recycling industry.

The operating characteristics of the eddy current separator

1. Adopt intelligent touch control cabinet system, frequency conversion control, more stable and reliable operation;

2. Adopt PLC programmable control, one-button start, easy operation;

3. The bearings are imported bearings with long service life and good operation;

4. The magnetic roller adopts effective magnetic system protection to prevent the magnetic system from falling off during high-speed operation;

5. The whole machine adopts special technology and is precisely built, and the noise and vibration are extremely small when the equipment is running;

CONTROL SYSTEM

Controlled by PLC system – Controls and operates the entire plant from its centrally located position and provides instant visibility to what each machine is doing in real time.

Unique Stop/Auto Reversal Feature – Protects against overfeeding and damage by non-processable items.

The features include low energy cost, large capacity, great costeffectiveness, low maintaining cost, good product quality, and so on.

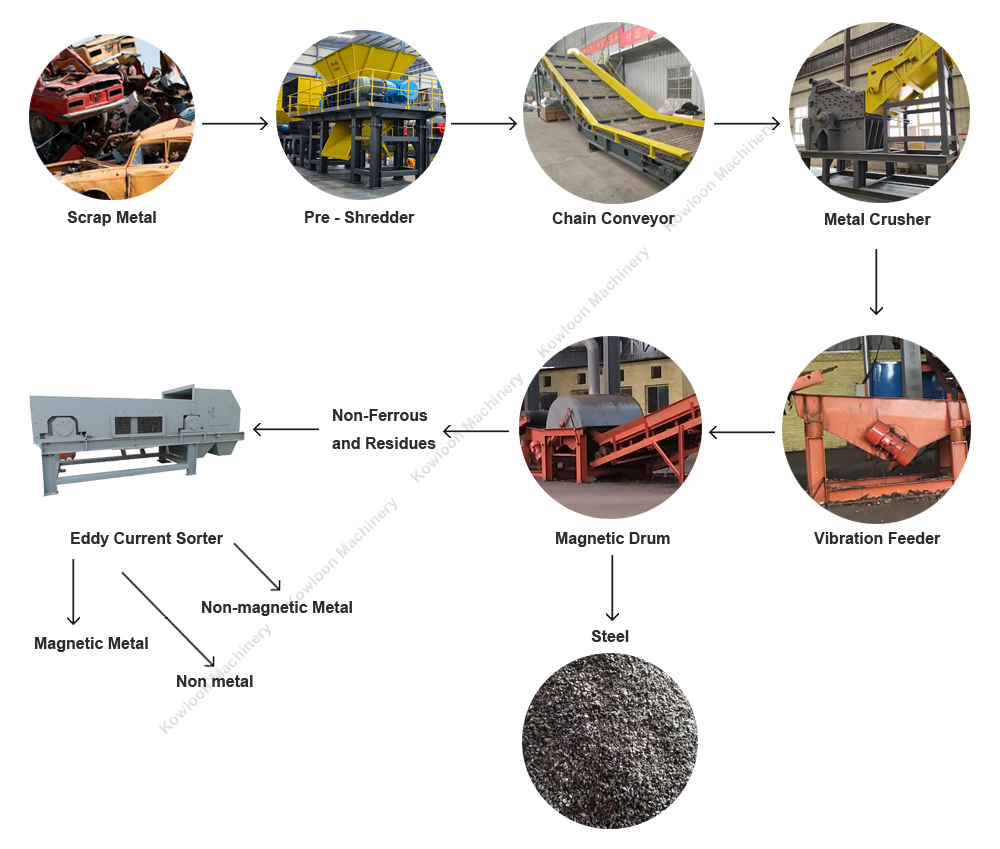

Production Process of the Scrap Metal Recycling Plant

1. The metal recycling line adopts double-shaft metal shredder, two-stage crusher, and Magnetic drum separator and Eddy current sorter etc.

2. Use separators and special structures to remove the foam and dust during the crushing period.

3. The scrap metal recycling equipment separates the ferrous metal by a magnetic separator.

4. A vortex separator is adopted by the waste recycling machine to separate the non-ferrous metal from nonmetal materials. Conduct innocent treatment by removing dust in concentrated air and filtering the gas by activated carbon.

If you are interested in the scrap metal recycling plant , please contact us. We have a variety of waste recycling plants, such as scrap car recycling line, tire recycling plant, solid waste recycling plant, Household garbage recycling line and more.

Technical Data

Metal Shredder Equipment Parameter ( Pre-Shredder )

|

Model |

JLSS1200D |

JLSS1500D |

JLSS2000D |

JLSS2600D |

|

Motor |

30kw+30kw |

30kw+30kw/55kw+55kw |

75kw+75kw/90kw+90kw |

110kw+110kw/160kw+160kw |

|

Gearbox |

Gearbox: planetary type, gear transmission |

|||

|

Shaft |

solid shaft, made of 40Cr, hardened and tempered |

|||

|

Shredder chamber (inner) |

1120x1000mm |

1450x1100mm |

1920x1250mm |

2425x1400 |

|

Rotor rotary speed |

6-8rpm |

6-8rpm |

4-6rpm |

4-6rpm |

|

Blade type |

Detachable type |

Detachable type |

Detachable type |

Detachable type |

|

Blade |

Dia.530mm |

Dia.530/560mm |

Dia.730mm |

Dia.730/900mm |

|

Lubrication system |

With automatic oil lubricator for gearboxes |

|||

|

Dimension |

3.2x2x1.9m |

4.04x2.45x2.6m |

5.48x2.79x3.05m |

7.74x4.12x4.72m |

|

Weight |

17000kg |

22000kg |

34000kg |

58000kg |

Metal Crusher Equipment Parameter ( Fine Crushing )

|

Model |

JLMC-200 |

JLMC-315 |

JLMC-450 |

|

Thickness of case plate |

30mm |

40mm |

50mm |

|

Thickness of screen |

60mm, material: cast steel, mesh 65*85mm |

100mm, material: cast steel, mesh 65*85mm |

100mm, material: cast steel, mesh 65*85mm |

|

Thickness of edge lining plate |

40mm |

50mm |

60mm |

|

Main shaft Diameter |

200mm,material:40Cr |

250mm,material:40cr |

280mm,material:40cr |

|

Rotor disc |

φ800mm, thickness 50mm, welding wear layer |

φ900mm, thickness 60mm, welding wear layer |

φ1200mm, thickness 80mm, welding wear layer |

|

Hammer |

10pcs, material: 13Cr2Mn, unit weight: 35KG |

10pcs, material: 13Cr2Mn, unit weight: 45KG |

14pcs, material: 13Cr2Mn, unit weight: 75KG |

|

Thickness of Forced feed plate |

16mm, hydraulic system |

20mm, hydraulic system |

20mm, hydraulic system |

|

Motor/control cabinet |

8P-200kw (1pcs), brand: WNM Soft starting cabinet, electrical components: Chint/Delixi |

8P-315kw (1pcs), brand: Simo - Slip Ring motorcyclo motor water resistance starting cabinet, electrical components: Chint/Delixi |

8P-450kw (1pcs), brand: Simo - Slip Ring motorcyclo motor water resistance starting cabinet, electrical components: Chint/Delixi |

|

Feed chain conveyor |

9000*1200mm,1pcs, power:7.5KW |

12000*1400mm,1pcs, power:11KW |

12000*1600mm,1pcs, power:11KW |

|

Vibrating discharge machine |

2500*1000mm,1pcs, power:3KW |

2500*1000mm,1pcs, power:3KW |

3000*1200mm,1pcs, power:4KW |

|

Discharge conveyor |

1000*6000mm,1pcs, power:4KW |

1000*6000mm,1pcs, power:4KW |

1000*6000mm,1pcs, power: 4KW |

|

Magnetic separation vibration feeder |

2000*1000mm,1pcs, power: 3KW |

2000*1200mm,1pcs, power: 4KW |

2000*1200mm,1pcs, power: 4KW |

|

Drum magnetic separator |

1000*650mm1pcs, power: 5.5KW |

800*1000mm 1pcs, power: 7.5KW |

1000*1000mm1pcs, power: 7.5KW |

|

output conveyor |

800*8000mm1pcs, power: 4kw |

800*8000mm1pcs, power: 4KW |

1000*8000mm1pcs, power: 5.5KW |

|

Slag removal conveyor |

500*8000mm1pcs, power: 3kw |

600*8000mm1pcs, power: 3KW |

650*8000mm1pcs, power: 4KW |

|

DMC-120 Filter bag type dust collector/Cyclone/pipe/fan |

1set power: 7.5KW |

1set power: 11KW |

1set power: 22KW |

|

Capacity |

4-6t/h |

8-10t/h |

10-15t/h |

Clients