Car Crusher Machine Scrap Waste Car Recycling Crushing Machine for Sale

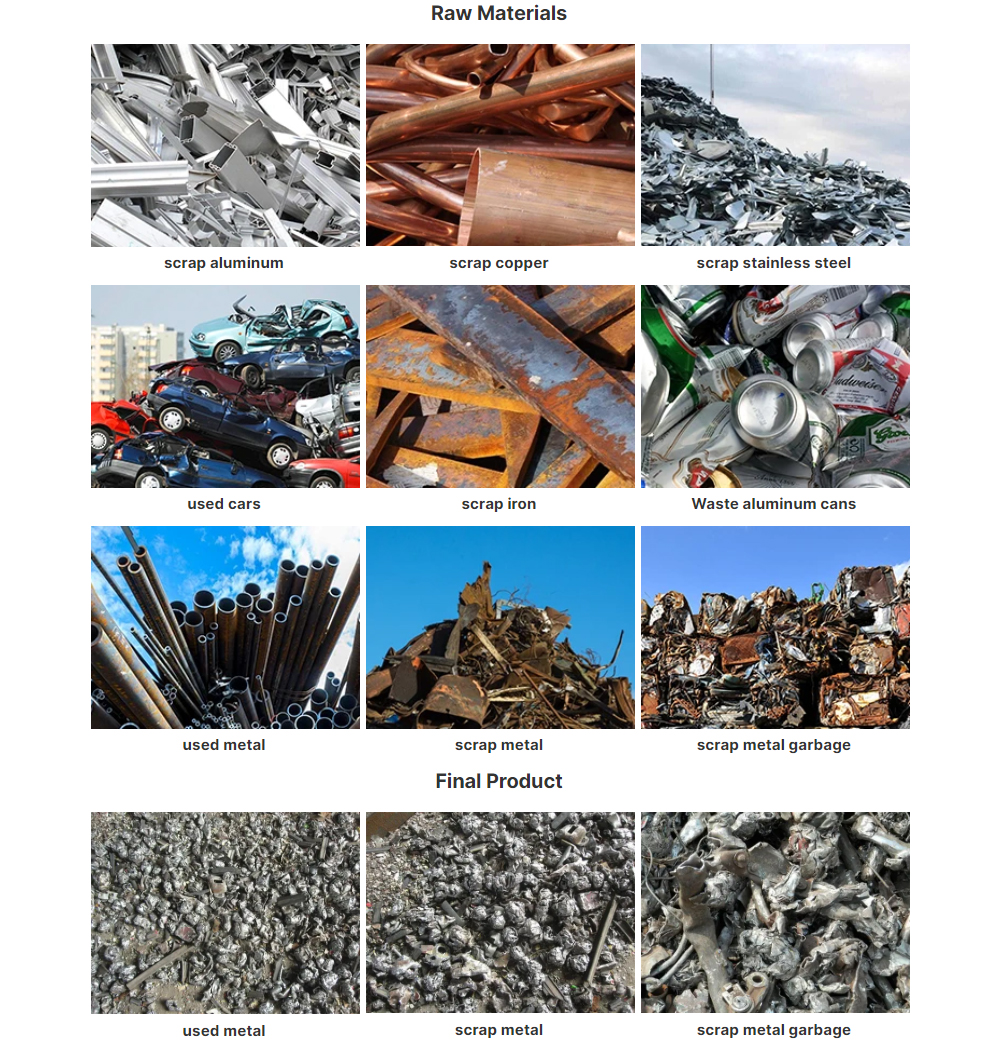

Application Materials :Waste car body, waste color steel tile, waste light and thin metal materials

Power :18.5-220 kw

Production :600-12000 kg/h

Crushing and processing, control material size, regular shape, high bulk density

- Fitted Solution and Offer , 24 Hours Online.

- Oversea Installation , Training on Request .

- Continue provide Wearing Parts and Service !

Video

Description

Scrap Car Crusher

【product details】

The scrap car shredder can crush and process scrap car bodies, scrap colored steel tiles, scrap light and thin metal materials, etc., and control the size of the materials to make them regular in shape, high in bulk density, and easy to sort into fine materials for ironmaking, Recycling in steel mills.

【Application Materials】

Bicycle frame, motorcycle frame, color steel tile, various scrap iron scrap, briquetting, etc.

【Power】18.5-220kw

【Production】600-12000kg/hproduct description

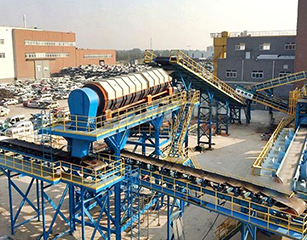

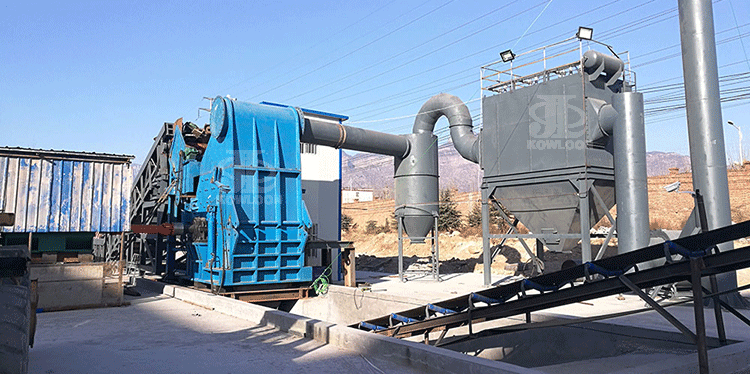

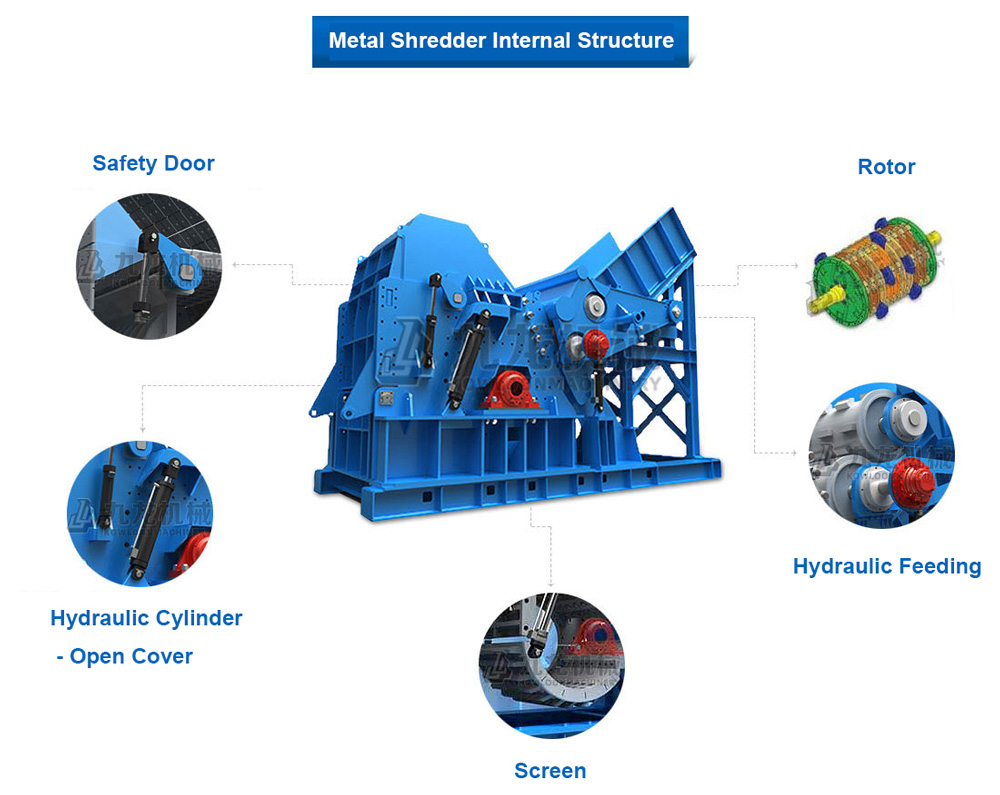

The scrap car shredder makes the scrapped cars reused, effectively solves the transportation difficulties, steelmaking difficulties, and furnace casting difficulties, and also brings benefits to environmental protection. It mainly consists of one car shredder, one production line and one magnetic separation equipment The machine is composed of a conveyor, a conveyor and a motor. The machine has a reasonable design and a generous appearance. The size of the feeding inlet can be modified according to the user's needs, and the material will not be returned and will not cause damage.

The scrap car shredder is a special scrap metal recycling shredder carefully developed by Jiulong Machinery based on many years of manufacturing experience.

Application areas: widely used in automobile recycling companies, scrap steel recycling companies, metal smelting, construction industry, metal recycling industry, etc.

Applicable materials: bicycle frame, motorcycle frame, color steel tile, carriage board, keel strip, color TV, refrigerator, washing machine, scrap angle steel, scrap square tube, filing cabinet, safe, car slot, packing block, electrical shell, cans , beer cans, cans, Sprite cans, Lulu cans, paint buckets, bicycles, motorcycles, car shells, color steel tiles, scrap angle iron, rolling shutters, iron boxes, etc.

Working principle

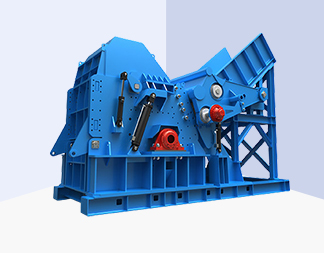

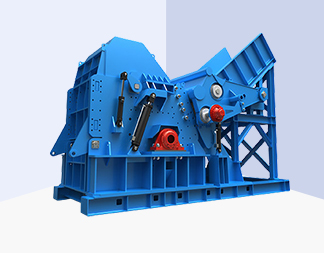

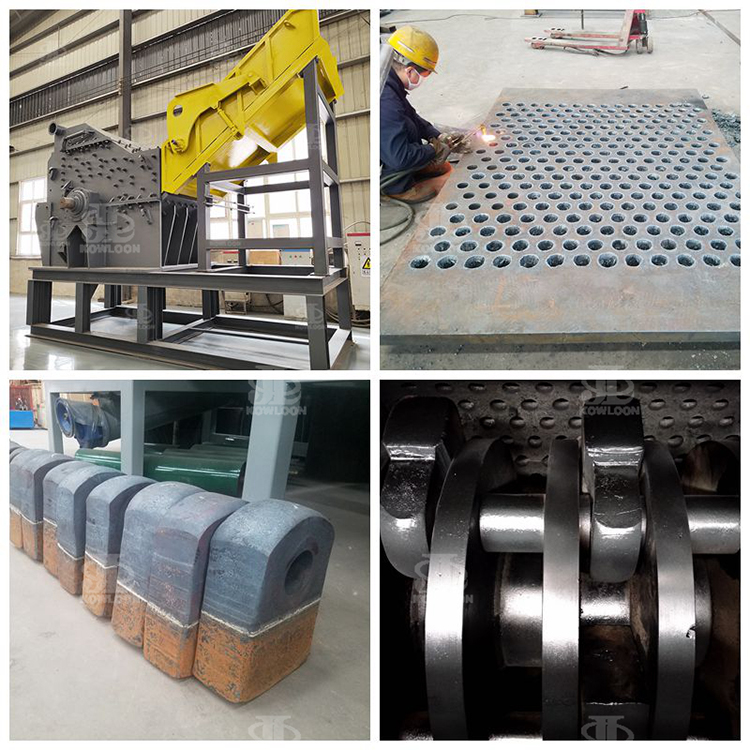

The scrap car crusher adopts the combination of fixed knife and movable knife. The fixed knife is S-shaped and fixed on the top of the cutter head. When the material enters the casing, it plays the role of forced feeding and forced crushing. The moving knife is a vertical head. When the material is torn strongly by the fixed knife, particles smaller than the screen will be formed during the beating process with the rotation of the turntable, which will be filtered into the discharge port through the screen. In order to be able to separate the iron particles and aluminum particles in the metal material, the conveying device equipped with the scrap car shredder is combined with the magnetic separation, which can separate the aluminum and iron in the metal material after being crushed by the scrap car shredder. At the same time, it passes through a dust collector to absorb all the patent leather and impurities, so that the crushed metal particles are clean and bright. In addition, the screen can be customized according to the material and user needs.

Performance characteristics

1. The scrap car crusher blade is a meshing blade refined with high alloy, which has a good crushing effect on any high hardness material;

2. The waste car crusher is driven by a geared motor, which saves 20% of the electricity compared to other can crushers;

3. The waste car crusher is installed with a foundation, and the startup is stable without too much noise;

4. The solid structure of the scrap car shredder and the densely clothed stiffeners ensure the strength of the box;

5. The scrap car crusher can be equipped with conveyor belt feeding equipment, which expands the scope of processing and recycling.

Technical Data

|

Model |

JLHC-200 |

JLHC-315—420HP |

JLHC-450—600HP |

|

Thickness of case plate |

30mm |

40mm |

50mm |

|

Thickness of screen |

60mm, material: cast steel, mesh 65*85mm |

100mm, material: cast steel, mesh 65*85mm |

100mm, material: cast steel, mesh 65*85mm |

|

Thickness of edge lining plate |

40mm |

50mm |

60mm |

|

Main shaft Diameter |

200mm,material:40Cr |

250mm,material:40cr |

280mm,material:40cr |

|

Rotor disc |

φ800mm, thickness 50mm, welding wear layer |

φ900mm, thickness 60mm, welding wear layer |

φ1200mm, thickness 80mm, welding wear layer |

|

Hammer |

10pcs, material: 13Cr2Mn, unit weight: 35KG |

10pcs, material: 13Cr2Mn, unit weight: 45KG |

14pcs, material: 13Cr2Mn, unit weight: 75KG |

|

Thickness of Forced feed plate |

16mm, hydraulic system |

20mm, hydraulic system |

20mm, hydraulic system |

|

Motor/control cabinet |

8P-200kw (1pcs), brand: WNM Soft starting cabinet, electrical components: Chint/Delixi |

8P-315kw (1pcs), brand: Simo - Slip Ring motorcyclo motor water resistance starting cabinet, electrical components: Chint/Delixi |

8P-450kw (1pcs), brand: Simo - Slip Ring motorcyclo motor water resistance starting cabinet, electrical components: Chint/Delixi |

|

Feed chain conveyor |

9000*1200mm,1pcs, power:7.5KW |

12000*1400mm,1pcs, power:11KW |

12000*1600mm,1pcs, power:11KW |

|

Vibrating discharge machine |

2500*1000mm,1pcs, power:3KW |

2500*1000mm,1pcs, power:3KW |

3000*1200mm,1pcs, power:4KW |

|

Discharge conveyor |

1000*6000mm,1pcs, power:4KW |

1000*6000mm,1pcs, power:4KW |

1000*6000mm,1pcs, power: 4KW |

|

Magnetic separation vibration feeder |

2000*1000mm,1pcs, power: 3KW |

2000*1200mm,1pcs, power: 4KW |

2000*1200mm,1pcs, power: 4KW |

|

Drum magnetic separator |

1000*650mm1pcs, power: 5.5KW |

800*1000mm 1pcs, power: 7.5KW |

1000*1000mm1pcs, power: 7.5KW |

|

output conveyor |

800*8000mm1pcs, power: 4kw |

800*8000mm1pcs, power: 4KW |

1000*8000mm1pcs, power: 5.5KW |

|

Slag removal conveyor |

500*8000mm1pcs, power: 3kw |

600*8000mm1pcs, power: 3KW |

650*8000mm1pcs, power: 4KW |

|

DMC-120 Filter bag type dust collector/Cyclone/pipe/fan |

1set power: 7.5KW |

1set power: 11KW |

1set power: 22KW |

|

Capacity |

4-6t/h |

8-10t/h |

10-15t/h |

Clients