Rotary Sand Gravel Drying Equipment Dryer Machine

Applicable Materials:

Fertilizer, feed, sand, mineral powder, coal slime, river sand, slag, coal, dry powder mortar, desulfurization gypsum and other materials

Application Areas:

Material drying in cement, mining, building materials, chemical industry, compound fertilizer production and other industries

- Fitted Solution and Offer , 24 Hours Online.

- Oversea Installation , Training on Request .

- Continue provide Wearing Parts and Service !

Video

Description

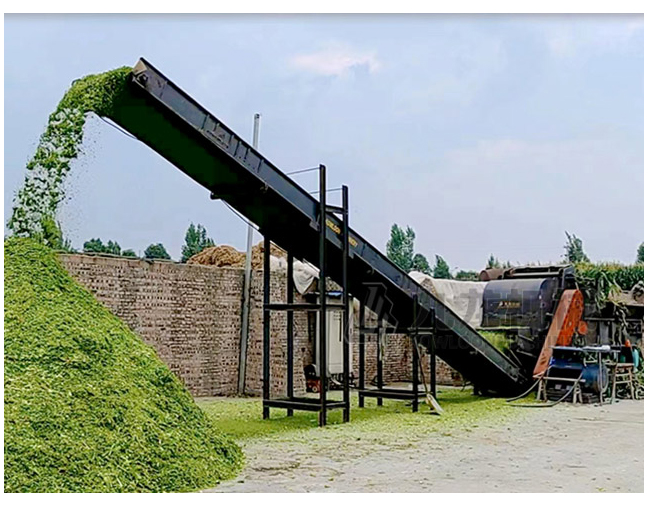

Sand and Gravel Dryer Equipment

Application areas:

Material drying in cement, mining, building materials, chemical industry, compound fertilizer production and other industries

Applicable materials:

Fertilizer, feed, sand, mineral powder, coal slime, river sand, slag, coal, dry powder mortar, desulfurization gypsum and other materials

Sand and gravel (quartz stone, cobblestone, river sand, yellow sand) are important raw materials in construction projects. With the requirements of urban development and construction, the types of mortar (dry powder mortar, plastering mortar, dry-mixed mortar, thermal insulation mortar) are different from each other. The demand is also increasing, and the sand and gravel dryer (sand drying equipment) came into being, and is widely used in sand making, building materials, metallurgy, mineral processing, chemical industry, cement and other industries.

Sand and gravel dryer is a very targeted dryer, generally suitable for granular materials, especially drying sand, sand, etc., the drying effect is better. At the same time, it has high efficiency, and can also be used to dry sticky paste materials or materials with high water content by partially mixing materials.

The advantages of the sand and gravel dryer are large production capacity, wide application range, small flow resistance, large allowable fluctuation range in operation, and convenient operation. There is a copy board on the inner wall of the sand and gravel dryer equipment. Its function is to copy and sprinkle the material, so that the contact surface between the material and the air flow increases, so as to improve the drying rate and promote the advancement of the material.

The heat carrier is generally divided into hot air, flue gas, etc. After the heat carrier passes through the dryer, a cyclone dust collector is generally required to capture the materials in the gas. If it is necessary to further reduce the dust content of the exhaust gas, it should be discharged after passing through a bag filter or a wet filter.

Performance advantage

1. The initial moisture of the material is 15%, and the final moisture is ensured below 0.5-1%. It is a favored product for various drying projects such as cement plant slag powder and dry powder mortar production line.

2. The temperature of the outer cylinder is less than or equal to 60 degrees, the temperature of the exhaust gas is less than 120 degrees, and the use time of the dust removal equipment bag is more than 2 times longer.

3. The fuel can be applied to white coal, bituminous coal, coal gangue, oil and gas. It can bake block, granular and powdery materials below 20-40mm.

4. The downstream drying method is adopted, the flue gas and wet materials enter the dryer from the same side, and the high-temperature flue gas can be used to obtain high evaporation intensity, the outlet temperature of the dryer is low, and the thermal efficiency is high;

5. Because the sand and gravel dryer is made of high-quality materials and has a novel style, the life of the dryer is also longer than that of the general dryer.

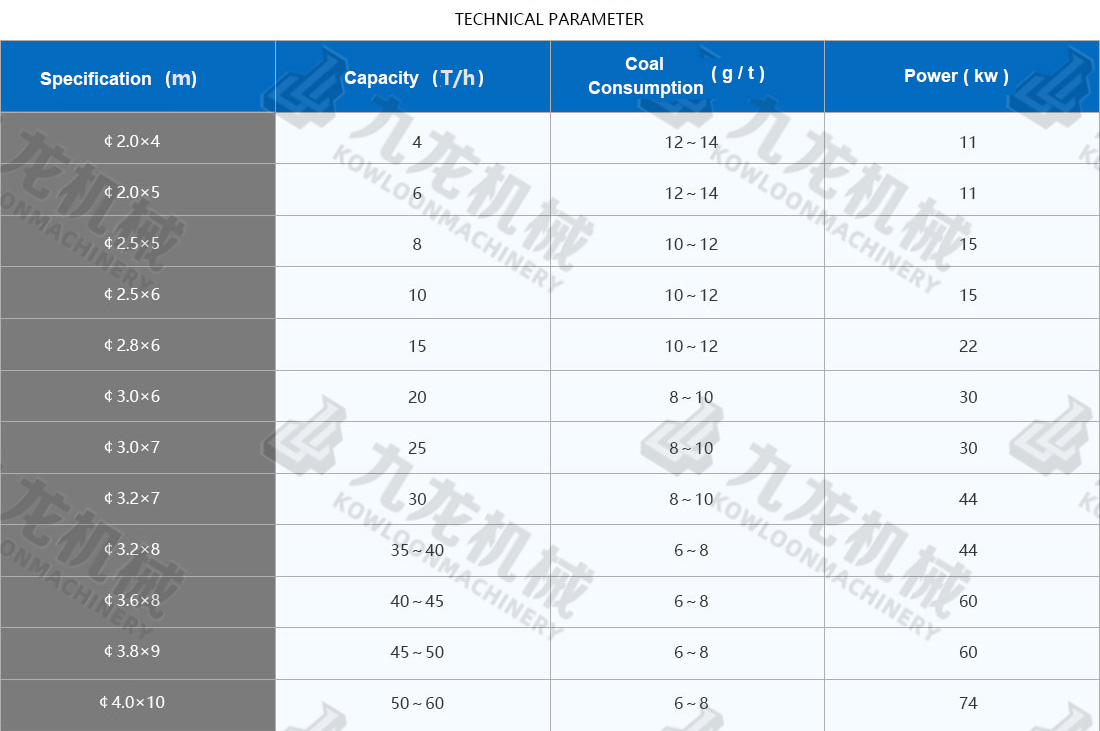

Technical Data

Clients